Welcome to Marine Exhaust Systems of Alabama

We custom fabricate and duplicate parts daily. If you have an old part you want duplicated exactly, or if you have an off the wall idea that you want to bring to life, we can help you. We can also design what you need given your chosen specifications.

If you have an outdated part, a part that is no longer cast, or a part that could be manufactured both faster and cheaper, please send the part to us and we will quote you a price. We recently redesigned the water cooled manifold on the Detroit 8.2.

Our work is top quality and our prices are more than competitive. We believe that there is no limit to what we can accomplish. We use only the best material and, in my opinion, the best welders and welding practices. There is no limit to the quality and durability of any machine part we manufacture.

We have been in business since the seventies and manufacture a wide variety of components. From water cooled exhaust manifolds to heat exchangers to custom components with nothing to do with any individual industry. Our company has had the pleasure to work directly with and for Caterpillar, Cummins, U.S. Navy, Army, Coast Guard, NASA, NOAA, Disney, and many other great companies too numerous to mention. We pride ourselves in our craftsmanship and ingenuity, so much so, that all of our products are backed by a one year warranty.

Our Engineering Team along with our Machine, Weld, Fabrication, Fitting, Bending, and CAD shops can build anything imaginable. In addition to all of our standard equipment we also have the following; 400Amp CNC Plasma Shape Cutting System, Tube Benders and End Finishers, Hydraulic Sheet and Plate Shears, Multiple Plate Rollers, 100 and 300 Ton Draw Presses, Complete Heat Treating System, and of course a complete CAD system. We would be glad to quote any of your fabrication needs and please, in the future, keep us in mind. We love what we do and we are sure it is evident in our work.

Marinization Kits

Give us almost any engine and we can design a Keeled Cooled and Heat Exchanger Cooled Kit including Water Cooled Manifold, Expansion Tank, Heat Exchanger, Raw Water Pump, Fan Guard, Water Inlets, Water Outlets, Wet Exhaust Ell’s, Wet and Dry Exhaust Risers, and etc… The design is then priced and you are quoted the prototyping cost as well as the purchase cost.

If all cost are covered, you retain propriety over the design, i.e. when someone wants to buy the kit they can only buy it through you, and in turn you would purchase the kit through us at the initial quoted price. We have marinized engines for various companies, individuals, independent small businesses, and not mention propriety marinization kits and parts for the original engine manufacturers including Caterpillar, Cummins, Isotta Fraschini, Hercules, and Daewoo, etc…

We recently designed Marinization Kits for the International 530E/Series 40, John Deere 6081, Hercules LDT 465, Daewoo DC24, DB33 and DB58, Ford BSD 666T, the Detroit Series 60 11.1. We are currently in the process of obtaining a Perkins 6.354.4 range four engine in house in order to redesign the marinization kit. We have completed numerous kits in the past, if interested in marinizing an engine please give Mark a call.

“We will need an engine for approximately two months.”

Looking for Kay Industries or Key Marine?

We bought out Kay Industries (CAGE Code 81212) some time ago and have all the patterns, drawings, and fixtures for Kay Industries Parts. All the Sk, Ak, DT Risers, Mufflers, elbows, and collector risers for a multitude of engines. Part numbers usually take the form of SK-1000.

Additionally, we have sources for most of the patterns and drawings for Key Marine Parts. If you have an old part that has the Key Marine Logo on it, please give us a call. Upon Key Marine Closing, they supplied us with a multitude of drawings etc. We can use their prints and build the unit using far superior material and in the process, hopefully save you some money, both long and short term.

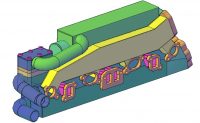

Collectors, Risers, and Elbows

“Given the original part or a detailed drawing We can quote you a price on almost any part. We build from only the best materials. For example, the inside liners in some of our risers we use Inconel 625. Inconel 625 is normally used in aerospace manufacturing and cryogenic applications, due to its strong resistance to sulfuric acid and corrosion. Inconel 625 does not rust or corrode in any way under any circumstance and it’s ability to withstand the formation of sulfuric acid. (When salt water combines with exhaust, sulfuric acid forms and eats a riser from inside out, while not damaging the outside jacket leaving the owner unaware of the internal leakage). For the water jacket we normally use Stainless Steel 316L, the marine industry standard. If you have any question regarding the material we use or if you are interested in getting a quote, please give us a call.”

Mark Coulson

Lead Mechanical Engineer

Turbochargers

If you’re having trouble finding a replacement turbocharger or if you’re looking for a new one, please let us know and we will be glad to source one for you.

We have various suppliers around the world who can offer parts at a fraction of the OEM cost.

Please e-mail your turbo make, model, and serial number to us along with the shipping address you would like the turbo’s ship to and we will reply with the pricing as soon as possible Please indicate if it is possible to send your old unit as an exchange. And as always please contact us if you have any questions.